Solve Modern Industry Challenges with

CI Precision

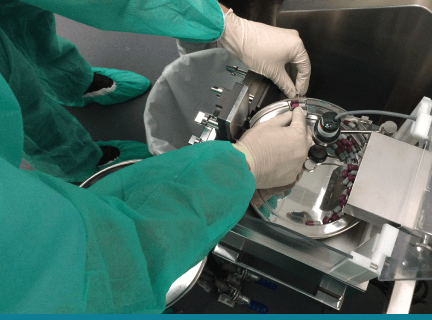

We take pride in supplying solutions that help our partners solve industry challenges and thrive in competitive sectors. Our specialist solutions address many of the challenges faced by those in R&D, clinical trials and production environments across sectors such as pharmaceutical, life sciences, industrial, aerospace, agritech and many more. Here are some of the key areas our products can help you with.

Achieve exceptional batch recovery savings

Achieving a high First Pass Yield can be challenging without the right technology and equipment. With our high-precision weight sorters, you can minimise scrap waste and costly reworks from failed batches. Our weight sorters work with items in any shape, size and format and can typically recover over 90% of a failed batch to help you realise substantial cost savings as well as improve manufacturing output quality and productivity.

Maintain excellent regulatory compliance

Complying with strict standards and regulations can be difficult when relying on manual operations and paper records. Our solutions automate and digitise the error-prone and time-consuming tasks, allowing you to catch errors early, investigate root causes more efficiently and identify compliance risks more effectively. With tamperproof record-keeping as well as automated data capture and timestamping to ensure data integrity, our MES solution provides a complete audit trail that helps you streamline your audit and validation processes as well as ensure procedural compliance.

Reducing the costs of compliance with automation in R&D

Achieving the highest levels of quality and ensuring compliance in R&D require checking the weight of every single item and maintaining error-free processes. Manual weighing and record keeping is time consuming, and a costly use of skilled lab technician’s time. Furthermore it presents challenges for data integrity and validation. Our precision weight sorters provide automated, attendant-free, 100% check weighing, creating tamper-proof electronic records and ensuring the highest quality standards cost effectively.

Maximise productivity and minimise delays

For manufacturers that look to do more with less, streamlining manual processes and eliminating paperwork can bring about large productivity improvements. Our powerful MES solutions help automate time-consuming and error-prone tasks such as weighing, sorting, data recording and post-checking. Not only can this help you improve resource management, but replacing paper-based systems can also enhance information management for better, more transparent performance monitoring and improved compliance.

Weight sort any dosage form

Our precision weight sorters can handle anything that you need them to: from the smallest to the largest and everything in-between, including tablets, capsules, soft gels and other formats. That even includes damaged, friable or broken product. Weigh any product batch without the need for costly change parts or special tooling.

Gain 100% control over quality

Having tight control over quality is crucial for rapid return on investment, regulatory compliance and your competitive edge. With the right processes and equipment, you can enhance quality control while reducing costs and improving production output. Our automated high-precision weight sorters and graders eliminate error-prone manual tasks to enforce 100% inspection regimes with detailed record-keeping that help to ensure accurate and reliable rejection of off-specification items.

Our Resources

Knowledge Hub

The latest updates and insights from our project team.

Our Work

Case Studies

Read how we are helping businesses like yours meet their challenges.

Automated, high-precision weight sorting for superior quality control

When Harwell Dosimeters wanted to control the manufacturing quality of their Alanine Pellets they chose CI Precision’s weight sorters to accurately weigh each pellet.

MoreGain total quality assurance in industrial parts manufacturing

SPIROL UK wanted to verify that their Coiled Spring Pins were manufactured to a consistently high weight quality to ensure robust quality assurance in their processes.

MoreMaintaining excellent accuracy and stability in experiments

Delft Solids Solutions needed a highly sensitive analytical instrument that can be used in research experiments for precise measurements of very small amounts of material.

MoreConnect with Us

Contact the CI Precision team today and book your individual project discovery session.