Weight Grading in Aerospace Research

Research engineers rely on the MX Precision Weight Grader to drive process improvements

Reducing carbon footprint

Many of the world’s airlines have committed to drastically reducing their carbon footprint and the urgency to adapt has put a lot of pressure on innovation within the aerospace and defense (A&D) industry. Companies are actively working on making aircraft with lighter structures and more efficient engines.

Whether you are working on incremental product improvements or researching entirely new areas, measuring the results can be one of your most challenging and time-consuming activities.

Weighing is sometimes overlooked but can be an excellent way of deriving other measurements or providing verification of key attributes.

Improving competitiveness

The incorporation of composite and new metal materials allows the manufacturing of lighter and more resistant components, two key parameters for improving competitiveness and differentiation in the A&D sector.

The weight of a component can be a measure to determine the composition, production quality, process improvements, and much more, that could not be picked up with other inspection methods.

Driving profitability

Current supply issues and the rise in raw materials costs and other input costs are driving down the aerospace and defense industry’s profitability. Companies must consider the need to cut costs and improve efficiency to remain viable.

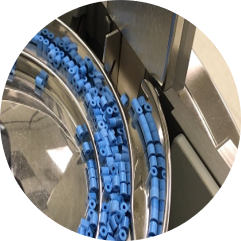

The MX weight grader’s unique ability to detect very small variations in a component’s weight at high speed is an efficient and cost-effective way of performing quality control.

A&D research engineers rely on the MX to help drive process improvements to optimise the manufacturing process with increased efficiency, less material wastage, and improved yield.

Supporting digital strategies

The acceptance of Industry 4.0 means the big 3 (Boeing, Airbus, and Lockheed Martin) and other stakeholders require equipment that supports data extraction and other value-added services that simplify their manufacturing operations.

With MX precision weight graders, you can gather complete, accurate data that allows you to analyse the results of changes, in the final product and at intermediate stages.

Where there are variability MX precision graders can be used to separate them into precise weight bands, so the variation can be controlled and optimised for subsequent processes.

Explore More

Continue Your Research

Explore our high-performance MX graders

Weigh, grade and sort industrial small parts with extreme precision at high speed with our dependable weight graders and improve your efficiency, quality and compliance.

MoreFind your local CI Precision partner

We work with partners around the world to provide expert local sales and support services. Contact us to find your local representative.

MoreIntroducing the new generation of industrial weight graders

A five-way precision weight grading system to weigh, grade and sort every small part up..

Contact UsNext Steps

To find out more, please contact CI Precision or your local channel partner.

Get contact detailsMeet us at an exhibition