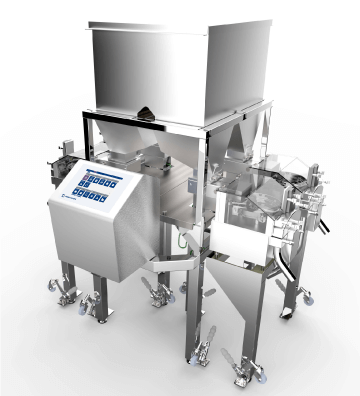

SADE SP weight sorters in action

Manual weighing can cost you more than you think

Any production downtime is costly

What can we help you with?

Why weight sorting?

Contact UsRecovering rejected product

Contact UsCost-effective compliance in R&D

Contact UsHealthcare Weight Sorting Division (WS)

Contact UsCan you sort my dosage form?

Contact UsWhy CI Precision?

Contact UsOperating in your environment

Contact UsBuilding a business case

Contact UsHealthcare Weight Sorting Division (WS)

Contact UsCan you afford to reinvest in your clinical trial?

Almac Pharma Services

Pharma Services Contractor Almac uses the SADE SP440 in R&D applications for weight sorting both tablets and capsules, where batch sizes can vary from 1,000 - 250,000.

Lorem...

MoreSynthon Chile

The SADE SP240 tablet and capsule weight sorter is used at Synthon Chile for specific markets that require additional quality verifications and for Internal Positive Controls.

MoreAspen Pharmacare Australia

Aspen Pharmaceuticals, Australian manufacturers of prescription medicines, use the SADE SP140 for statistical profiling in tablet manufacturing and batch reclamation.

MoreScrapping your batch due to a weight failure

Solutions

White Paper – Individual OSD weight sorting is a vital process for quality control.

Next Steps

To find out more, please contact CI Precision or your local channel partner.

Meet us at an exhibition