Back to news

Back to news

The risks of purchasing a used checkweigher

Purchasing a used checkweigher?

What are the risks in purchasing used checkweighers, in a highly regulated sector such as the pharmaceutical industry, and is it really a viable alternative?

Cost or investment?

Purchasing an old generation, and therefore a less accurate/efficient checkweigher, in order to save some money is the first mistake to avoid.

Money saved while purchasing cannot be compared to the loss due to false rejects and product waste.

Lifespan

Poorly maintained equipment will shorten the operational lifespan with unexpected breakdowns, increasing outage duration and costs.

Purchasing a new checkweigher with a planned preventative maintenance schedule from the manufacturer is essential to saving you downtime and money over the long term.

Obsolescence

Due to componentry obsolescence, previous generations of weight sorters may no longer be supported by the manufacturer and/or be expensive to fix, service, or replace.

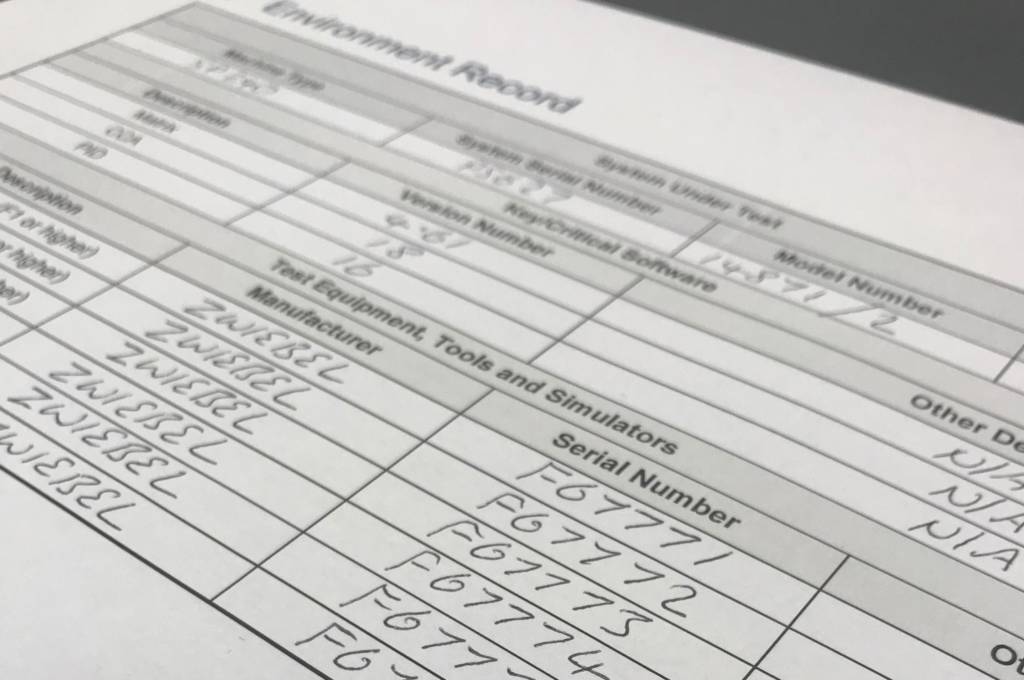

CI Precision announced at the beginning of March 2017 that we can no longer provide service support or parts for the SADE P2/P4 range of weight sorters due to obsolescence of both electronic, mechanical, and software components.

Out-of-date technology

Why purchase an old generation, and therefore a less accurate/efficient checkweigher, and not take advantage of new technology?

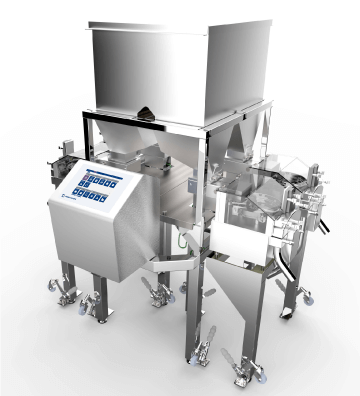

The P range has been superseded by the SADE SP range which began production in 2005. The SADE SP series includes more advanced technologies providing improved performance, increased functionality and a better overall user experience that would provide substantial benefits to a business.

Still compliant with regulations?

When was the last time that the used checkweigher calibrated? And was it by a qualified engineer?

CI Precision offers a calibration service with the SADE SP range of weight sorters. Our trained engineers will perform accuracy and performance tests to verify your weight sorter is weighing accurately and issue a traceable calibration certificate. This will ensure precise, consistent results while extending the life of the equipment and keeping unexpected bills to a minimum.

History

It is very unlikely that the used checkweigher will come with a full history of which drugs have been weighed creating a risk of future cross-contamination. Indeed, most of our customers would not consider allowing equipment into their plant that could have been contaminated particularly with high potency or antibiotics drugs.

Some of our customers would prefer to purchase a second weight sorter to avoid cross-contamination with products within their own site.

Cleanability

A used weight sorter will undoubtedly suffer from surface abrasions hindering future cleanability.

A new SADE SP weight sorter has been designed to ensure superior levels of GMP compliance and hygiene.

SADE SP - excellence assured

A new SADE SP machine is the very essence of peace of mind. With all the assurance of knowing that you are the first to use this machine, fully tested to manufacturers specification, comprising the latest parts and materials, with the certainty of full compliance, enjoy the ultimate in buyers’ confidence. Why settle for second best when your reputation is at stake?

With the best combination of accuracy and speed in its class, return on investment is a certainty.

- compatible with the latest regulatory stipulations

- optimised operational designs

- 21st century operating systems

- data integrity and security

- contemporary surface and materials specifications

- vastly improved durability and reliability

- comes with the warranty, backup and on-site support

SADE SP weight sorters in action

Get in touch or find a local partner

We can help you find your nearest representative at the touch of a button.