Back to news

Back to news

Ci-DMS chosen to help deliver productivity and GMP compliance in pharmaceutical manufacturing plants in the USA and Thailand

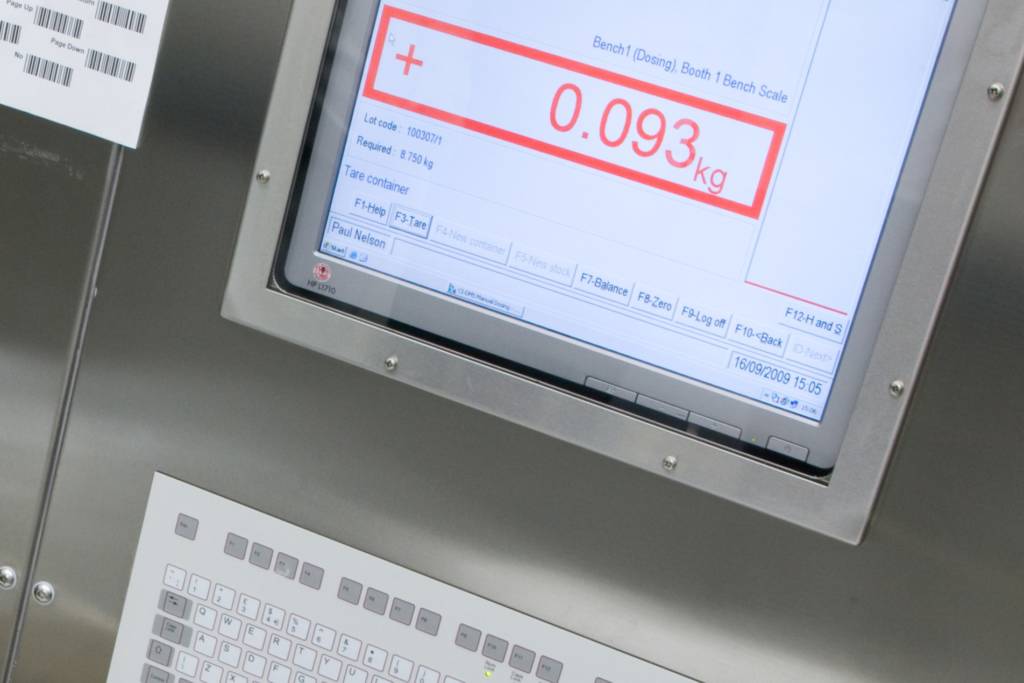

CI Precision was selected to implement Manufacturing Execution Systems (MES) in the USA and Thailand. The Ci-DMS weigh & dispense MES module is highly configurable and controls the dispensing of raw materials for pharmaceutical production and provides an electronic batch record for manufacturing operations. Ci-DMS uses barcodes to identify the correct raw materials and interacts with scales to electronically record the quantity dispensed, removing the errors associated with manual data entry. Ci-DMS provides productivity gains by removing the need for a second checker. Through a bidirectional interface Ci-DMS automatically updates the ERP system for all material consumed, replacing the current manual data entry processes, reducing data errors and eliminating delays in updating the stock record. By enforcing standardised processes Ci-DMS helps improve GMP compliance and the audit trails and reporting functions provide rapid analysis of any deviations. In both projects CI Precision provided installation and validation support in accordance with GAMP principles and compliance with relevant regulatory standards. Will Eaden International Sales Manager at CI Precision comments:“These implementations demonstrate our commitment to supporting pharmaceutical manufacturers with high quality cost effective software systems at a global level.”CI Precision is based in Salisbury UK and has over 45 years’ experience developing software systems for pharmaceutical manufacturers. For more information about CI Precision’s Ci-DMS MES suite please telephone +44 (0)1722 424100 or e-mail sales@ciprecision.com

Als PDF herunterladen

Download PDF