Back to news

Back to news

University of Birmingham uses Microbalances for Testing High Temperature Alloys and Coatings

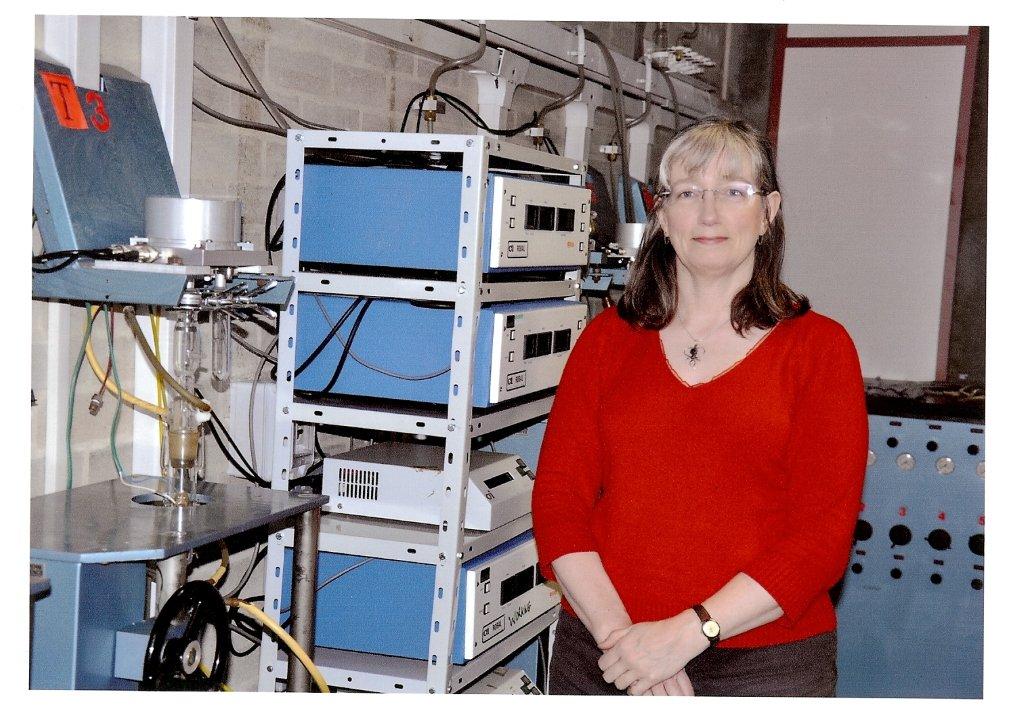

The University of Birmingham, established in 1900 as the UK’s first civic or ‘redbrick’ university, was founded to provide a skilled, professional workforce and groundbreaking research that benefits regional industries. Dr Mary Taylor, a post doctoral researcher in the High Temperature Oxidation Group in Metallurgy and Materials, is currently working on two projects in collaboration with industry using thermo-gravimetric systems from CI Precision. These projects entail the testing of high-temperature metal alloys and coatings for use in the hot sections of turbine engines and heat exchangers. Testing procedures include both high-temperature oxidation and constant stress creep testing. A novel method of determining the high-temperature creep properties of coatings has been developed within the Group. Dr Taylor works with Prof. Hugh Evans who transferred an impressive array of CI thermo-gravimetric analysers, consisting of MK2 microbalances Robal controllers and furnaces, and constant stress creep rigs from the Berkeley Laboratories in Gloucester some 20 years ago. These systems were set up to house the furnace controlling thermocouple within the silica reaction tube, adjacent to the specimen. Dr Taylor comments,“This gives us greater confidence in temperature control and enables us to relate weight change during the cooling cycle to specific temperature transients. The rapid heat up gives us the ability to study high temperature reactions.”Commenting on her decision to purchase further units from CI, Dr Taylor adds:

“All of the original thermo-balances were from CI Electronics (as CI Precision was then known) and have been very reliable and thus when we were in a position to upgrade and replace this equipment they were the first company we approached. The flexibility of their equipment meant it could easily be installed into the existing housing with minimal adaptations.”Two of the High Temperature Oxidation Group’s newer CI Microbalance Systems, purchased in 2005, have similar thermocouple arrangements but their latest two acquisitions installed in 2012 are being used with exotic gases. Dr Taylor explains:

“In these systems I have positioned the thermocouples outside the reaction tube level with the specimen to give me more space inside the tube but still have the level of confidence in controlling the test temperature.”CI Microbalance kits consist of a MK2-M5 Microbalance, DISBAL control unit, LabWeigh software package, Universal Attachment glassware, cables and silica accessories plus a furnace and furnace controller. CI also provides the high level of technical support and advice, gained from many years experience, that is sometimes necessary when building custom analytical instruments. For further information about microbalance kits and accessories from CI Precision, please telephone +44 (0) 1722 424100, or e-mail sales@ciprecision.com

descargar como pdf

Download PDF